Technology

Evalution

*In addition to the data shown below, we have much more various experimental data, so please ask us anytime.

1

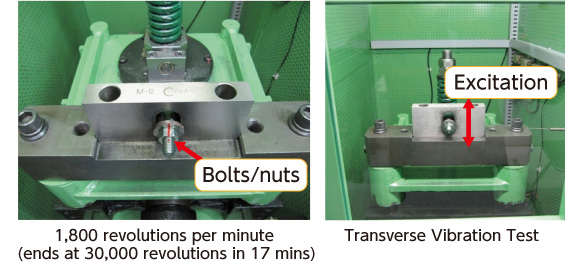

NAS Vibration Test (JQA Kansai Testing Center)

Regularly conduct vibration tests in accordance with US Aircraft Standard NAS3350.

Motiontite clears the vibrations of 1,800 rotations per minute and 30,000 rotations in 17 minutes.

NAS Vibration Test

2

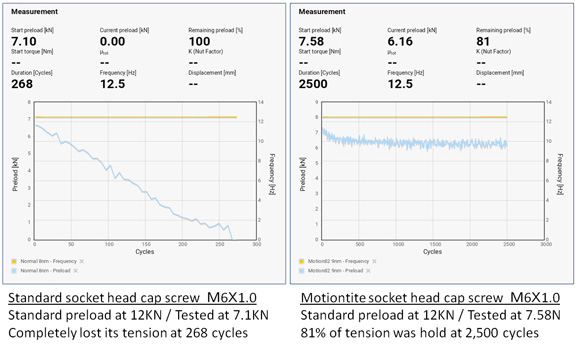

Junkers Vibration Test

Junkers Vibration Test

| Test Bolt M6×1.0 |

Standart Bolt |

Motiontite Type 82 |

||

|---|---|---|---|---|

| Seating Torque (Nm) | 10 | 8 | 10 | 9 |

| Start preload (kN) | 8.67 | 7.10 | 8.43 | 7.58 |

| Duration (Cycles) | 323 | 268 | 2,500 | 2,500 |

| Load after test (kN) | 0.00 | 0.00 | 7.16 | 6.16 |

| Remaining load (%) | 0 | 0 | 85 | 81 |

| Break off Torque (Nm) | 0 | 0 | 10 | 9 |

| Test date: | June 15, 2017 |

|---|---|

| Test equipment: | Vibration Masters J120T |

| Conditions: | Displacement±0.25mm Frequency12.5Hz Shut down at 2,500 cycles |

| Test Bolt: | M6 x 1.0 PC 12.9 Socket Head Cap Screw with hex recess (Standart tension at 12KN) |

| Test nut: | Nut height of 8mm (used in the actual application) |

| Evalution criteria: | Apply vibration of which standard bolt may lose its tension at 200 - 300 cycles to Motiontite. It is determined as it pass the test if Motiontite have more than 80% of the given preload after 2,500 cycles |

Junker test comparison diagram

3

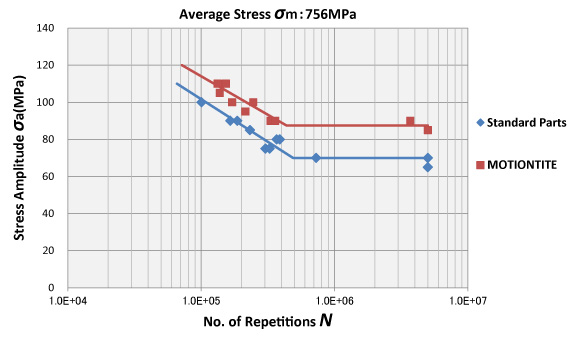

Fatigue Test: JISB1081 (Nagoya Municipal Industrial Research Institute)

When repeated stress is applied to a fixed bolt, the upper limits of stress which can be withstood from an infinite number of repeats is called the "fatigue limit".

A bolt's fatigue limit is obtained from the S-N curve, and it is generally considered that if there is no fatigue failure after 107 times or 5 x 106 times, it will permanently not be destroyed, and the stress amplitude at this points is the fatigue limit value.

Fatigue Test: JISB1081

Testing machine: SHIMADZU Servo-Pulser

*Motiontite showed improvement by approx. 25%

4

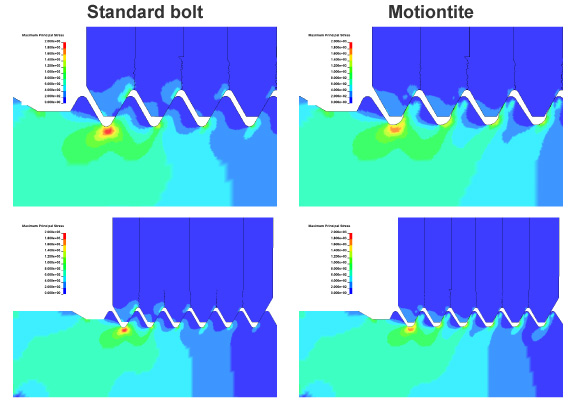

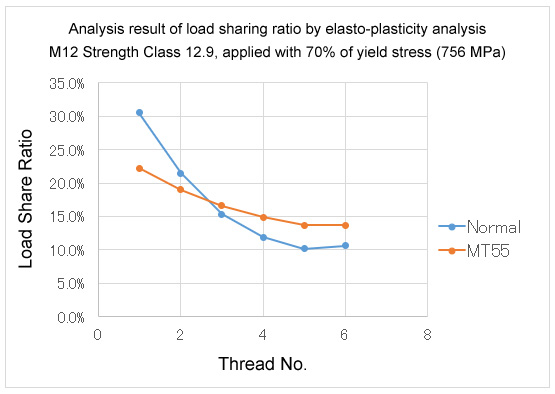

Load Share Ratio (Nagoya Municipal Industrial Research Institute)

Stress analysis (elasto-plasticity analysis)

"Maximum principal stress" analysis by Nagoya Municipal Industrial Research Institute (LS-DYNA)

Thread Load Share Ratio

The lower the load sharing ratio for the first thread to mesh is, the more the fatigue strength is improved.

1. Assumption of load

Strength class 12.9

For fatigue, mean stress of 756 MPa set to 70% of yield stress was applied.

| M12 | |

| TS (MPa) | 1200 |

| YS (MPa) | 1080 |

| Mean stress (SF) | 0.7 |

| Fatigue mean stress (MPa) | 756 |

| Effective cross-section area (mm2) | 84.3 |

| Load (N) | 63730.8 |

| Load (N/rad) | 10143.1 |

2. Results of load sharing ratio

| Product name | Standard product | Motiontite | ||

|---|---|---|---|---|

| Nominal diameter | M12 | M12 | ||

| Strength class | 12.9 | 12.9 | ||

| N/rad | % | N/rad | % | |

| 1 | 3094.99 | 30.5 | 2250.60 | 22.2 |

| 2 | 2176.13 | 21.4 | 1923.49 | 19.0 |

| 3 | 1559.50 | 15.4 | 1682.50 | 16.6 |

| 4 | 1207.65 | 11.9 | 1511.13 | 14.9 |

| 5 | 1030.07 | 10.2 | 1388.59 | 13.7 |

| 6 | 1079.77 | 10.6 | 1391.33 | 13.7 |

| Total | 10148.11 | 100 | 10147.64 | 100 |

*Motiontite has load sharing ratio more averaged than standard product. Thus, Motiontite has improved fatigue strength and is less likely to break.

5

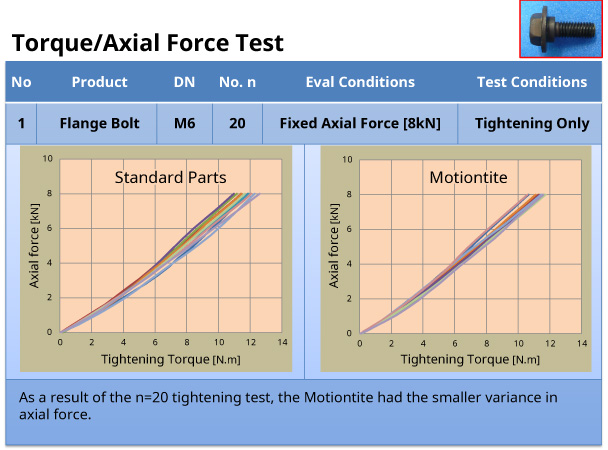

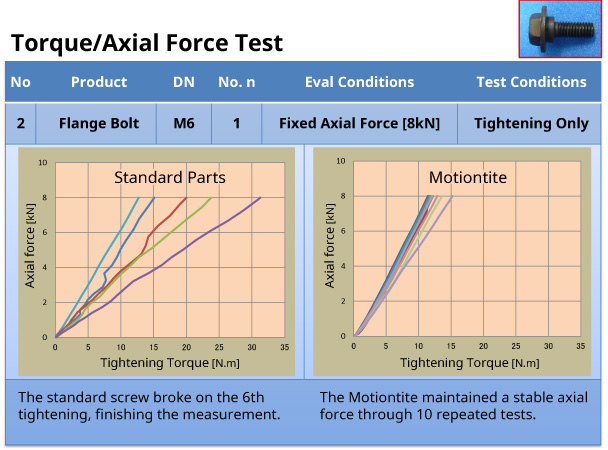

Torque/Axial Force Test

The degree of axial force variance differs greatly depending on the surface type and whether there has been surface treatment, but here a comparison test was conducted without any surface treatment or lubrication.

Screw Tightening Test n=20

Screw Tightening Test n=1

(repeat test)

6

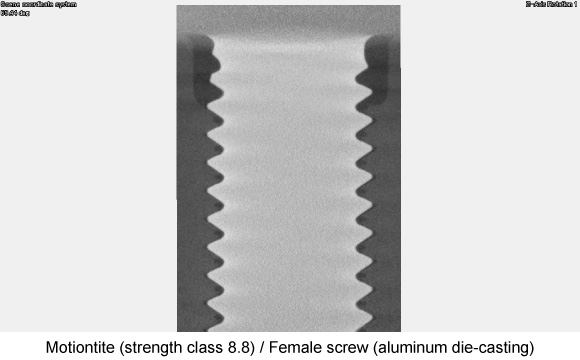

Computed tomography image (CT image)

Tightened state between Motiontite and a female screw was taken as a CT image.

Tightened state shown by CT image